Economic Fumed Silicone Rubber for Molding

Characteristics:

- Compliance with FDA

- Good transparency and mechanical properties

- Good yellowing resistance and stable processability

Main Applications:

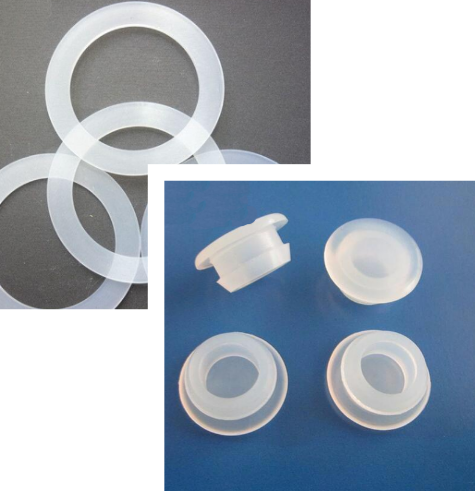

- Molded products with high requirement for transparency

Typical Data:

| Properties | Product Data | Test Method | |||||||

|---|---|---|---|---|---|---|---|---|---|

| NE-9530 | NE-9540 | NE-9550 | NE-9560 | NE-9570 | NE-9580 | NE-9590 | |||

| Appearance | Transparent , no extraneous matter. | Visual Inspection | |||||||

| Density, g/cm3 | 1.06~ 1.10 | 1.09~ 1.15 | 1.12~ 1.18 | 1.14~ 1.20 | 1.17~ 1.23 | 1.18~ 1.25 | 1.19~ 1.26 | ASTM D792 | |

| Curing | Hardness, Shore A | 30±2 | 40±2 | 50±2 | 60±2 | 70±2 | 80±2 | 86±2 | ASTM D2240 |

| Tensile Strength, MPa ≥ | 8.0 | 8.5 | 8.0 | 6.0 | ASTM D412 | ||||

| Elongation at Break, % ≥ | 600 | 500 | 400 | 300 | 200 | 120 | |||

| Tension Set, % ≤ | 8 | 6 | |||||||

| Tear Strength , Die C kN/m ≥ | 15 | 20 | 25 | 20 | 10 | ASTM D624 | |||

| Post- curing | Hardness, Shore A | 32±2 | 44±2 | 55±2 | 66±2 | 74±2 | 84±2 | / | ASTM D2240 |

| Tensile Strength, MPa ≥ | 6.5 | 7.0 | 8.0 | 7.0 | / | ASTM D412 | |||

| Elongation at Break, % ≥ | 500 | 400 | 300 | 200 | 150 | / | |||

| Tear Strength, Die C kN/m ≥ | 10 | 16 | 18 | 16 | / | ASTM D624 | |||

| Compression Set, 180℃*22h ≤ | 58 | 50 | 48 | 45 | 35 | ASTM D395 | |||

| Rebound Resilience,% ≥ | 50 | 45 | 40 | 35 | / | ||||

| Volume Resistivity, Ω ▪cm ≥ | 1×10 15 | IEC 60093 | |||||||

| Dielectric Strength, kV/mm ≥ | 20 | IEC 60243 |

Physical data in the above table is for reference only