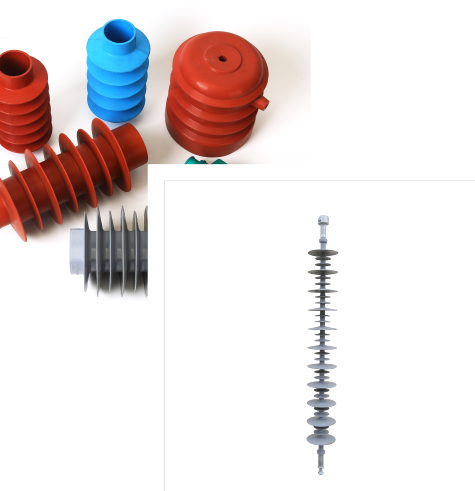

Electrical Insulating Silicone Rubber

Characteristics:

- Good processability

- Good electrical insulation properties

- Good tracking & erosion resistance

- Good hydrophobicity and flame retardancy

Main Applications:

- Various composite insulators, lightning arresters, insulators and high- & low-voltage electrical fittings for electrical lines of railways and urban light rails.

- Type 1 is applicable to press molding, and Type 2 is applicable to injection molding.

Typical Data:

| Properties | Product Data | Test Method | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Electrical Insulating Rubber | General Purpose Electrical Insulating Rubber | Common Electrical Insulating Rubber | |||||||||

| NE-T-1 NE-T-1U | NE-T-2 NE-T-2U | NE-C-1 NE-C-1U | NE-C-2 NE-C-2U | NE-D-1 NE-D-1U | NE-D-2 NE-D-2U | NE-E-1 NE-E-1U | NE-E-2 NE-E-2U | ||||

| Appearance | Product inherent color, no extraneous matter. | Visual Inspection | |||||||||

| Density, g/cm3 | 1.48~1.56 | ASTM D792 | |||||||||

| Hardness, Shore A | 62±4 | 60±4 | ASTM D2240 | ||||||||

| Tensile Strength, MPa ≥ | 4.5 | 4.0 | ASTM D412 | ||||||||

| Elongation at Break, % ≥ | 260 | 280 | 260 | 280 | 220 | 240 | 220 | 240 | |||

| Tension Set, % ≤ | 2.0 | ||||||||||

| Tear Strength, Die C kN/m ≥ | 13.0 | 12.0 | ASTM D624 | ||||||||

| Volume Resistivity, Ω▪ cm ≥ | 7×10 14 | 5×10 14 | 3×10 14 | 1×10 14 | IEC 60093 | ||||||

| Dielectric Strength, kV/mm ≥ | 22 | 20 | 18 | IEC 60243 | |||||||

| Dielectric Loss , tg δ ≤ | 3×10 -2 | 6×10 -2 | 7×10 -2 | IEC 60250 | |||||||

| Dielectric Constant | 3~4 | ||||||||||

| Tracking Resistance &Erosion resistance | 1A4.5 grade | pass | IEC 60587 | ||||||||

| Erosion Depth, mm ≤ | 2.5 | ||||||||||

| Flame Retardancy, 3mm | FV-0 | IEC 60695-11-10 |